Suitability and function

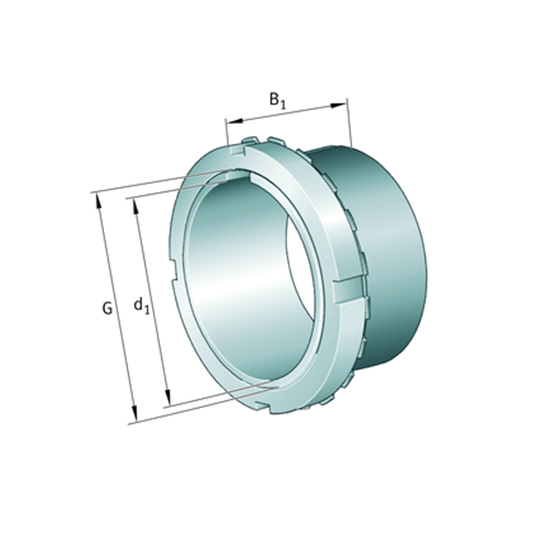

Adapter sleeves are suitable where bearings with a tapered bore are to be located on cylindrical shafts. In this case, the bearing is pressed onto the adapter sleeve until the required reduction in radial internal clearance is achieved. Adapter sleeves require no additional means of retention on the shaft. The bearings can be positioned at any point on shafts with a constant diameter.

If adapter sleeves are used with a support ring to DIN 5418 on stepped shafts, the bearings can be axially located to high accuracy. In addition, this gives simpler dismounting of the bearings.

Design features

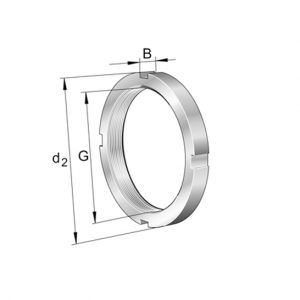

The tensile strength of the adapter sleeve material is at least 430 N/mm2. Adapter sleeves are slotted and have a shaft thread for the locknut. Depending on the series, the outside surface of the adapter sleeves has a taper of 1:12 or 1:30.

Adapter sleeves

| Series | Taper on the outside surface |

|---|---|

| H2, H3, H23, H28, H30, H31, H32, H33, H38, H39 | 1:12 |

| H240, H241, H242, H248, H249 | 1:30 |